Even if you’ve only ever dabbled a little bit in Bavarian beer, you will have stumbled upon the Hofbräuhaus in Munich, owned by the State of Bavaria, and with a beer hall in the heart of the city. But then you look further, and realise that there’s also a Hofbräuhaus Traunstein 75 minutes outside of Munich, and then there’s of course Weißes Bräuhaus. But how were these “court brew houses” established?

It all actually started with a bit of a brewing crisis. Starting from 3 September 1571, brewing in Munich was totally banned. That year’s rye harvest was rather poor, and barley was needed as a substitute to feed the population. Brewing white or brown beer was seen as a waste, and thus completely stopped through a Ducal order.

This brewing ban remained in place until 1580 when it was partially lifted. Of course, the Duke and his court still needed beer. So for the Duke, beer from Zschopau in Saxony was ordered, and the Nuremberg-based trading house Unterholzer facilitated the delivery of Ainpöckischpier from Einbeck from 1573 until 1589.

The court servants though got different beer: grain from the Duke’s storehouse was given to breweries, in particular the religious orders of the Franciscans and the Augustinians, and the brewer Georg Mänhart who held the title of “court brewer”. With that grain, these breweries were ordered to brew beer of the best quality to be delivered to the court.

Soon after Duke Wilhelm V. took office in 1579, he inquired about which breweries in the Bavarian Forest were brewing “white Bohemian beer” and where they got their brewing ingredients from. A commission of 4 people produced a report in 1581 that listed all the white beer breweries in the designated area as well as those that belonged to the Prince-Bishopric of Passau. In 1586, the Duke gave a brewing privilege to the Schwarzenberg family and their male descendants that allowed them to brew white wheat beer, a privilege that otherwise only the Degenberg family held. At the same time, he also inquired about the general profitability of white beer. An earlier report handed to him noted that brewing white beer was considered to be a waste, but could be turned into a profitable business.

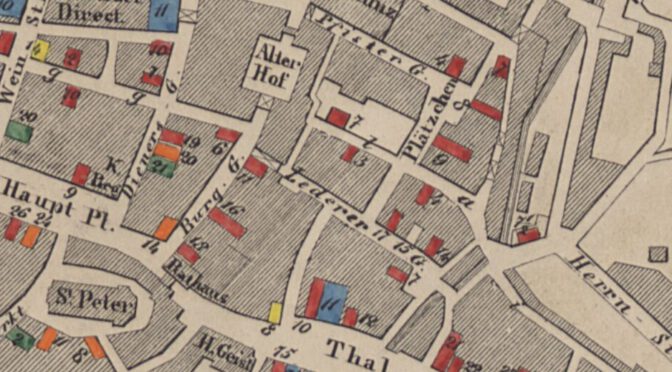

In the end, Duke Wilhelm V. remained cautious and only founded one brewery in 1589, the Hofbräuhaus in Munich for brewing brown beer, but building works for it only started in 1591. When the new brew house started operating, the previous court brewer Mänhart lost much of his business and fell into poverty, but was compensated for it with an annual payment of 100 florin a year.

When the Degenberg family went extinct in 1602 through the death of Hans VIII. Sigmund of Degenberg, Duke Maximilian I. set a plan in motion to gain control over white beer brewing in Bavaria. He was much more ambitious and had already looked into white beer brewing before taking office in 1597, as Bavaria was close to bankruptcy and he saw white beer as a profitable way of making the Bavarian Duchy rich again.

Before even the Degenberg inheritance was settled, he immediately continued paying the brewers at the Degenberg brew houses to keep up brewing operation, even though he legally did not own them. Only in 1607, he came to an agreement with the heirs of the Degenberg family, in which he was allowed to purchase the Degenberg breweries for 82,000 florin while cancelling a debt of 20,000 florin of the heirs. Maximilian I. now owned 3 white brew houses, in Zwiesel, Schwarzach and Linden.

Already in 1602, brewers from the Schwarzach brewery were ordered to Munich to teach the Hofbräuhaus staff how to brew white beer and to brew the first batches. The first court-brewed white beer was then sold in Munich on 16 October 1602, directly from the Ducal cellar. A separate white brew house was finally built in 1607 and a dedicated brewmaster for white beer was hired.

A newly built brew house in Gossersdorf that opened in 1600 and interestingly had not been banned by the court (they only banned the brewer from using domestically grown wheat) was sold to Maximilian I. in 1602.

At that time, the court in Munich had already forgotten about the Schwarzenberg brewing privileges granted in 1586, but when their family was able to provide them with original documents, Maximilian I. offered to buy their brew house in Winzer which was finalized on 29 April 1603.

Now owning all the white brew houses of the Degenberg and the Schwarzenberg families, he was the exclusive brewer of white beer in Bavaria. Well, almost, because there were nine communal brew houses in Lower Bavaria (the remnants of the communal brew house system in parts of Bavaria are nowadays better known as Zoigl) that historically also had a customary right to brewing white beer. The Duke also managed to subjugate them and forced them to share their revenue through a duty they had to pay. These nine brew houses were located in Viechtach, Regen, Kötzting, Furth im Wald, Neukirchen bei Hl. Blut, Eschlkam, Schönberg, Grafenau and Hals.

On top of that, more white beer breweries were established: in Mattighofen, the brown brew house was converted to producing white beer in 1607. In the summer of the same year, building works started in Kelheim for a new brewery which started brewing white beer in April 1608, while in Traunstein, an existing building was bought and turned into a brewery in 1611.

By 1612, Duke Maximilian had established a formidable network of state-owned breweries: not only was there the Hofbräuhaus in Munich that produced brown beer, but he also directly owned nine white brew houses and received a passive income from nine more communal white brew houses. Technically speaking, these were all court brew houses, and a dense network of them stretched over Old Bavaria that only got extended with more breweries over the years.

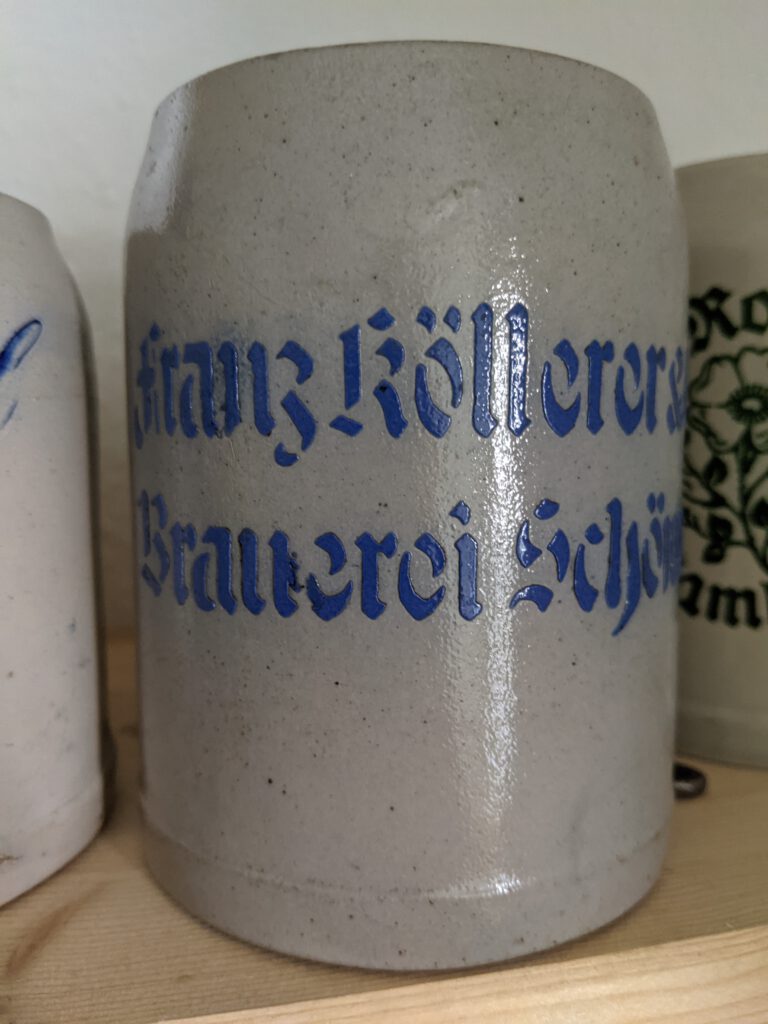

Some of them are still around: the white beer brewery in Traunstein was destroyed in 1704, rebuilt and eventually sold in 1820. Since 1896, it has been owned by the Sailer family and run as Hofbräuhaus Traunstein.

The “white brew house” in Munich kept operating next to the Hofbräuhaus and was leased to brewers. The last one was Georg Schneider. When the buildings of the white brew house were to be repurposed in the 1870s, he simply bought the rights for it from the court and moved to another building, the former Maderbräu building on Im Tal, just a few hundred metres away from the old brewery, which made it easy for his existing customers to visit the new place. The old Maderbräu building was renamed Weißes Bräuhaus (white brew house) and became the headquarters for the Schneider family brewer. In 1928, the Schneider family bought the white brewhouse in Kelheim, another formerly state-owned brewhouse which became their main brewery after World War II, and which they now claim to be the oldest white brew house in Bavaria.

What remains though is that the Hofbräuhaus is still around, even though ownership has changed, as the Bavarian King transferred it to the Bavarian State in 1852. The white beer privilege has long been broken, but even of these formerly privileged white brew houses, some are still in operation, the one in Kelheim even still dedicated to the production of white wheat beer.