Carinthian Steinbier (stone beer) is a very unique but extinct beer tradition in Austria, and probably the only farmhouse brewing tradition that survived long enough to be documented by historians and brewers alike. At the same time, Carinthian Steinbier was also brewed commercially, by a number of local breweries in Carinthia, with some stone beer brewing also documented in adjacent Styria.

Stone beer brewing is based on the principle that hot, glowing stones were used to heat up liquid in simple wooden vessels. This approach allows heating up a mash even without the availability of a metal kettle, something that would have been unavailable or prohibitively expensive for the vast majority of farmers for a very long time. It is considered to be the most primitive way of brewing, but at the same is probably also one of the oldest ways of brewing beer. If you’re interested in the general history and technique of stone beer brewing in Europe, I can recommend the excellent book Historical Brewing Techniques by Lars Marius Garshol, or his article How stone beer was brewed. I’ve previously also discussed Carinthian Steinbier in my book Historic German and Austrian Beers for the Home Brewer.

Carinthian Steinbier is interesting because it survived for a fairly long time, until 1917 to be exact, despite repeated attempts to completely supplant it with what was called “kettle brewing”, i.e. brewing involving metal kettles. During other research, I recently stumbled upon a 1962 article that is probably the most detailed description of Carinthian Steinbier tradition that I’ve found so far.

In Die Steinbiererzeugung, ein ausgestorbenes Gewerbe in Kärnten (lit. “stone beer production, an extinct industry in Carinthia”), Josef Grömmer discusses Steinbier brewing in Carinthia, the common brewing practices over time including the last few surviving breweries up to the demise of Steinbier in Carinthia. I will try and summarize the article here and highlight what I would consider to be important in these accounts.

Steinbier brewing used to be the standard mode of beer brewing in Carinthia until the 18th century, when empress Maria Theresia permitted kettle brewing to one brewer Simon Jessernigg in Klagenfurt, Carinthia’s capital. Farmhouse-brewed Steinbier seems to have been common in Carinthia for ages, but at least from the 14th century on, it was also done on a commercial basis and provided hundreds of people in Klagenfurt alone with jobs during the 18th century. Authors in the 19th century sometimes described Steinbier to be a drink purely consumed by the ethnically Slovenian population (Carinthia has been ethnically mixed between a German and Slovenian population, a fact that has caused massive political tensions especially during the 20th century and to a certain extent up to this day), but this was heavily disputed by others.

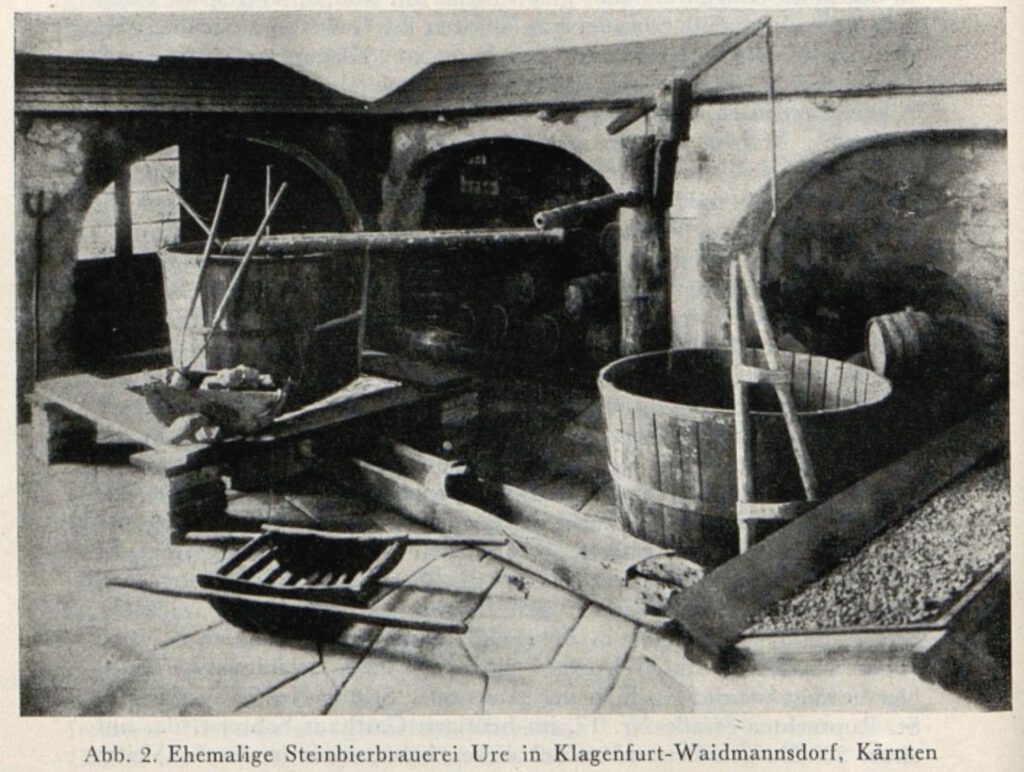

Steinbier brewing in Carinthia only ended in 1917, but interestingly not because of difficulties in sales, but rather because raw material had become unavailable. This was a problem of the Austrian brewing industry in general during World War I. The largest brewery, Schwechater, had to brew “beer” from broad beans, potato starch, various types of syrup, sugar beets or even plum jam due to a general malting prohibition that had been enacted in 1916. This also meant the end for the last two Steinbier breweries, Kaschitz and Ure, both located in Waidmannsdorf, nowadays a district of Klagenfurt.

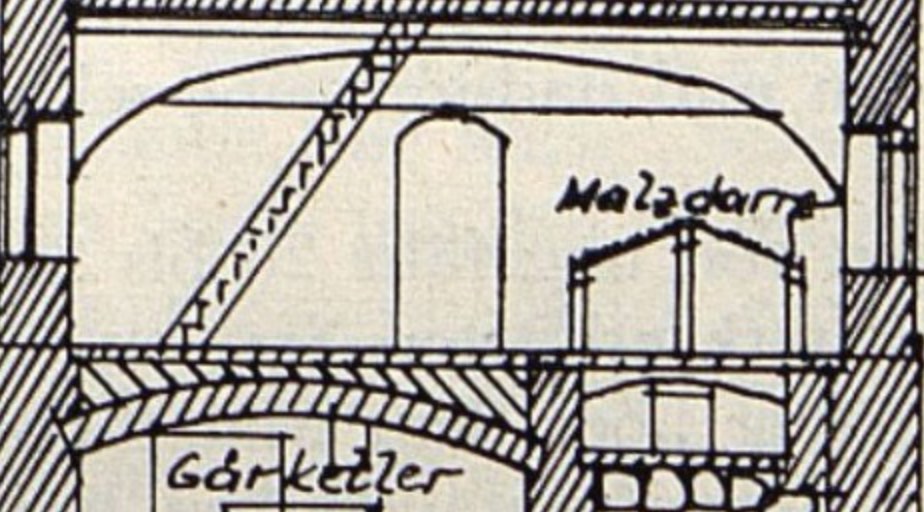

As for the Carinthian Steinbier brewing process itself, it is fairly well-documented. Grömmer’s articles even provides sketches of a complete brewhouse as well as a photo of the Ure brewery that had been fully preserved in the Technical Museum in Vienna.

Brewing of course started with malting. The common grains that were used were barley, oats and wheat. Depending on the brewery, differerent ratios of these grains were used, such as 60%/25%/15% barley/wheat/oats, while others simply used a third per grain type. Earlier reports from the 18th century say that brewers at the time used oat malt exclusively.

The grains were steeped and then let to sprout. In modern malting practice, the grains would get turned regularly, but not so much in Carinthia: the grains were mostly let to sprout by themselves, which made them get stuck together. Historic brewing literature calls this “Filzmalz”, or “felt malt” (like the textile). This was done for a particular reason: the kilns used were extraordinarily primitive smoke kilns. These kilns didn’t even have a metal grid or mesh, but instead only consisted of wickerwork set up in the form of a slightly sloped roof. Due to the shape, this construction was called a “Satteldarre” (lit. “saddle kiln”). We can see the specific form of this kiln even in Grömmer’s sketches:

The malt was kilned for 24 hours using cherry wood for the fire and was then stored without removing germs or rootlets. Apparently, the germs quickly reabsorbed moisture which made it hard to actually properly crush the malt, so it often only got squeezed open.

The breweries themselves were rather minimalistic in their equipment. One brewery was reported to only have the following brewing equipment: two large vats, one small vat, 15 pointed conical casks, one bag, one pump with a bucket, two carriers for stones, one “Grantner” (a trough to collect wort), one small vessel to scoop stuff, one brick underlay for a large cask, one kiln, two pliers to pick up stones, two forks to pick up stones, one wooden mash stirrer, one open fireplace and one lantern.

We know how the brewing itself worked thanks to Fritz Kaschitz, who in his 20s was brewing foreman in a Carinthian Steinbier brewery and brewed his last batch of Steinbier in 1917. In the 1960s, he was described as “Carinthia’s last living Steinbier brewer”. He gave account about Steinbier brewing in 1955.

Brewing was done like this: 600 kg of malt (1/3 barley malt, 1/3 oat malt, 1/3 wheat malt) were coarsely crushed. At 23:45 in the evening, the fire was started to heat up the stones. It took about 2 to to 2.5 hours to bring them up to full temperature when they were glowing red. The specific fire wood used here was pine. To pick up the stones, long pliers were used, while to carry the stones around, wooden carriers were used that had been watered for several hours to prevent them from burning.

On the bottom of the mash tun several juniper branches were put. They needed to be as fresh as possible. If they were too dry, they would lose their needles and lose their function as mash filters. They were held down by stones, and then water was added at a temperature of 62 to 75°C. Then hot stones were added to bring the water to a boil, and then 7 kg of hops were added. The hot stones were not fully submerged, so the hops were “roasted” for one minute. To prevent them from burning, more water was slowly added, then the mash tun was covered and left for 10 minutes.

During this break, a few small stones were added to a small vessel and water was added, then another bigger vat was put over it for steam-cleaning.

After 10 minutes, the mash tun covers were removed and mashing in started. Under constant stirring, the crushed oat malt was added. Stirring had to be vigorous to prevent the malt from settling in the juniper branches. More hot and cold water was added. Only then, the barley malt was mashed in, and in some circumstances, also small amounts of roasted malt.

The mash was then carefully stirred for 30 minutes. At the same time, the wheat malt was mashed in with tepid water in a smaller vessel. Later, hot stones were added to both vessels to slowly increase the temperature up to boiling. The stones were carefully placed at different places to prevent the mash from scorching. The small vessel with the wheat malt was then left until the morning, and only then mixed back into the main mash. The big mash vessel was then brought to a complete boil using stones of weights up to 20 kg. This usually took until 4am, followed by a rest until 6am.

At 6am, the tap (really nothing more than a bung) was slowly opened and the first wort was drawn. Any wort that wasn’t clear was scooped back into the mash vessel. The clear wort was then collected in the Grantner and left to cool a bit until it was moved to the fermenter. Then the mash was sparged using more hot water, and more wort was collected in the Grantner until it eventually ended up in the fermenter.

The original gravity of this unboiled wort was measured at 6° Balling, while the last runnings were at 1.2° Balling. The whole brewing process was supervised by a tax officer who measured volume as well as original gravity, the basis for taxation.

In the fermenter, the wort was left to cool. Fermenters were previously washed with hot water, then cleaned with a brush and rinsed with cold water, and finally put over bits of burning juniper branches, with a stake on the side to allow fresh air to sustain the little fire.

When the wort was at 22°C, yeast was added. The yeast was usually repitched from the bottom of the serving casks, but every two years, the yeast was replaced with new yeast from a Weißbier brewery from Munich. Fermentation was done for 7 to 10 hours, after which the beer was filled into smaller serving casks which then got bunged up. Fermentation times varied, and especially during the colder months, would take place over a longer time period and much lower temperatures as low as 10°C.

When the beer casks were tapped, they were highly carbonated, and the beer was poured with lots of foam, usually at serving temperatures of 15 to 18°C. Besides a slightly sour flavour, a subtle smoke flavour was also noticeable, even more so when the beer was served cold. Especially during warmer seasons, the beer had a tendency to go sour very quickly. It never kept well, and tapped casks needed to be finished within 2 days.

There were of course variations of this process. One example is the 1905 article Vom Steinbier by R. Dürnwirth, which is what I’ve used as the basis for the Steinbier recipe in my book. But Mr. Kaschitz’s account describes the process in the last few years of Steinbier brewing in Carinthia.

Hi Andreas

perhaps this is already known to you but I thought I’d post it anyway:

https://braumagazin.de/article/spiel-mit-dem-feuer-kaerntner-steinbier-rekonstruiert/

All the best

Tilo