Yesterday, I brewed a Kellerbier, a recipe that I had developed myself but was based on a number of inspirations that I picked up over the last year, such as water profile, mash profile and ingredients.

The grist I chose was based on what I had heard about Knoblach, as they apparently use 50% Pilsner and 50% Vienna malt in their pale lagers. I just liked the idea of adding that bit more malt complexity to a pale beer.

The water profile was based on what Stefan Zehendner talked about at HBCon 2024. Fortunately, my Berlin tap water is already as hard as it should be on the calcium side, all I had to do was to add magnesium. Epsom salts are the way to do that.

The hops I chose were Aurum, a relatively new variety (first approved in 2020 and probably a bit lost in the whole COVID troubles) that is a daughter of Tettnanger with a “highly fine” hop aroma. It apparently has a high disease resistance and better agronomic properties in hotter, drier climates. From what I remember reading, it is expected to take over other varieties like Tradition and Perle, so I thought I’d better try it out now.

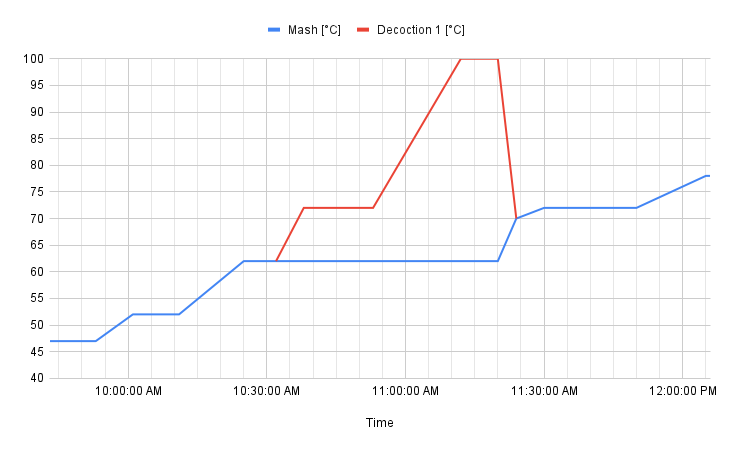

And finally, the mash profile: instead of doing my typical double decoction, I thought I’d try out the Mönchsambacher mash profile Stefan Zehendner described at HBCon 2024. Only when I actually used it, I realised how low-key brilliant it is. It basically goes like a normal multi-step mash: start with a protein rest, then heat up to 62°C for the beta amylase to do much of the conversion, followed by a rest at 72°C for the alpha amylase. This forms dextrins for body and also gets glycoproteins into solution for better head retention. Finish by heating up the mash to denature most of the enzymes.

If this is done as a multi-step infusion mash, the temperature steps are simple done by heating up the mash and stirring. The difference at Mönchsambacher is that the step from 62°C to 72°C is done as a decoction instead: about a third of the volume is drawn off and heated up, briefly rested at 72°C for 15 minutes, then brought to a boil and boiled for 5 minutes until it is mixed back into the main mash. The main mash still remains at 62°C until mixing back.

So what’s so brilliant about it? Well, the whole mash overall takes about the same time, no matter whether done as multi-step infusion mash or as single decoction mash. But most importantly, a part of the mash is boiled, causing Maillard reaction products to be formed. It’s really the best of both worlds: more Maillard products while not spending most of the brew day on extensively boiling decoctions.

So what’s the downside? Well, efficiency. I’ve not noticed any significant increase in efficiency between multi-step infusion mash and single decoction mash. The enhanced double decoction (which involves boiling two thirds of the whole mash) I normally on the other hand use gives me a bump of about 4-5 percentage points in efficiency. To compensate for that, I just need to buy 10% more in malt. At homebrew scale, those additional costs are very manageable (about €1).

This very positive experience made me rethink my approach to decoction mashing for German beer styles. I think I will stick to double decoction as a mash profile for Czech styles for maximum intensity, but for German styles, single decoction seems absolutely sufficient and saves me 1 to 1.5 hours of time.

One thought on “The Brilliance of Mönchsambacher’s Mash Profile”