Yesterday, I half-jokingly tweeted that two UK breweries best known for brewing German-style beers brewing a collaboration Vienna Lager is proof that 2021 is the year of Vienna Lager.

This actually made me reflect a bit on what happened since I published my book about the beer style. The book itself was very well received. I really feel like it filled a gap, and cleared up a lot of confusion about the style’s history. Of course, it takes a while to spread that knowledge, and I still come across some of the old myths around Vienna Lager that I was able to dispel.

Red Willow Brewery were the first ones to contact me about their own Vienna Lager. They had recently brewed one (named Meaningless, because of the Ultravox lyrics “This means nothing to me / Oh, Vienna” and all their beer names end with -less), and then found out about my book which they liked a lot. They were happy to send me a sample, and it was a good beer. Maltiness and bitterness were on the low end of the scale, but it’s certainly the kind of beer of which I’d have many more in one session, and thus in my opinion represented the spirit of Vienna Lager, to be an easily drinkable, flavourful beer that you can just enjoy with no fuzz.

One of the more surprising requests got to me just after Christmas when Rune Lindgreen of People Like Us reached out to me to get input on a Vienna Lager recipe. They were in the process of developing a coffee-infused Vienna Lager, certainly not the most traditional approach to the style, and wanted to get their base recipe counter-checked. I didn’t really have to do much, as the recipe looked fairly solid (I won’t go into details, but mostly Vienna malt as base malt, with small amounts of a few specialty malts). Then COVID hit me really bad, and it took me a while to recover from that, but a few months ago, I received several cans of the beer. Even though I’m not much of a coffee drinker, I was really impressed by this rather unusual interpretation: the base beer tasted exactly like I’d expect a modern Vienna Lager, some maltiness, balanced hop bitterness, well-attenuated, all with a distinct Vienna malt character, while the coffee added a particular roasted bitterness with some fruitiness that was enjoyable even for me.

By far the biggest surprise though was when Westerham Brewery from Kent got in touch with me. They had read my book, and took this line as a challenge:

As of 2020, no maltings is known to produce a Vienna malt using a historic variety such as Haná or Chevallier.

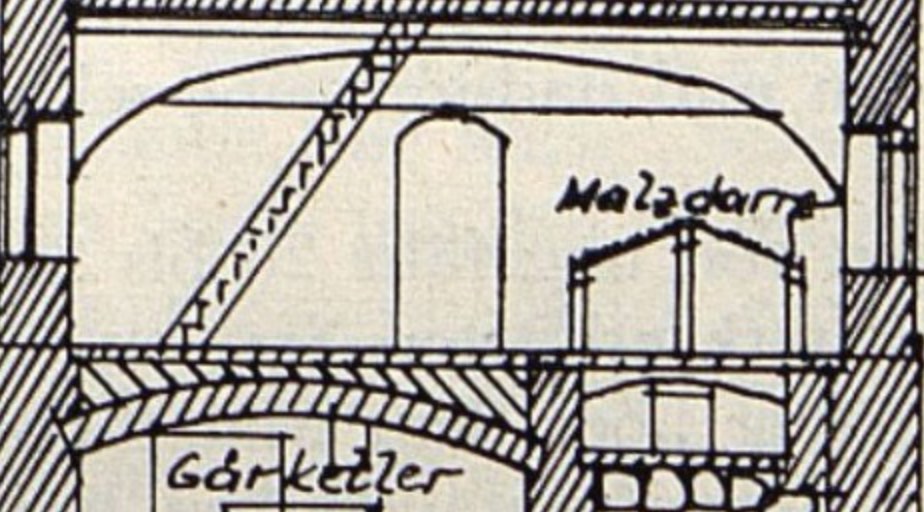

They got in touch with Crisp Malt, a traditional Norfolk-based maltings that still employs traditional floor malting techniques. In recent years, Crisp Malt has put considerable work in reestablishing old heritage barley varieties and turning them into quality malts. One of these heritage varieties is Haná, the old Moravian barley variety that was hailed the most in Austria for its brewing qualities. Crisp Malt had previously released a Haná Pilsner malt, and so they had the resources to also create a Haná Vienna malt. Long story short, Westerham brewed a Vienna Lager from it, and Crisp Malt started selling the malt as part of their small batch series. While I didn’t do much other than research and write a wee book, I’m full of joy to have inspired a brewery and a maltings to collaborate and produce a malt and a beer based on what I’ve written. I think it also speaks for the beer style that not only people are enthusiastic about it, but that even businesses are willing to take on some risk in recreating it true to the historic original.

Earlier this year, I was able to visit my family in Austria, which also gave me the chance to try out Austrian supermarket Vienna Lagers. That’s right, ever since two large Austrian breweries, Ottakringer and Schwechater (actually the original brewery where Vienna Lager was invented, nowadays owned by Heineken), released modern recreations of the style, Vienna Lager is a thing again back in its country of origin. I tested this by simply going to a local supermarket and picking two 4-packs of canned Vienna Lager. Austrian Märzen (similar to Bavarian Helles, but with a more robust bitterness) and Radler are still dominating Austrian supermarket beer aisles, but the fact that I can get two different mainstream brands in a regular supermarket shows that there is a niche for the style that goes way beyond craft beer.

Both beers are very similar: some maltiness, very well-attenuated, balanced bitterness, good body, a pale amber colour that is just a tad darker than e.g. Pilsner Urquell, and incredibly easy drinking and refreshing. The Schwechater version even features a picture of Anton Dreher, the inventor of the style, together with an extremely brief description of the style’s history. A tiny bit of beer history education.

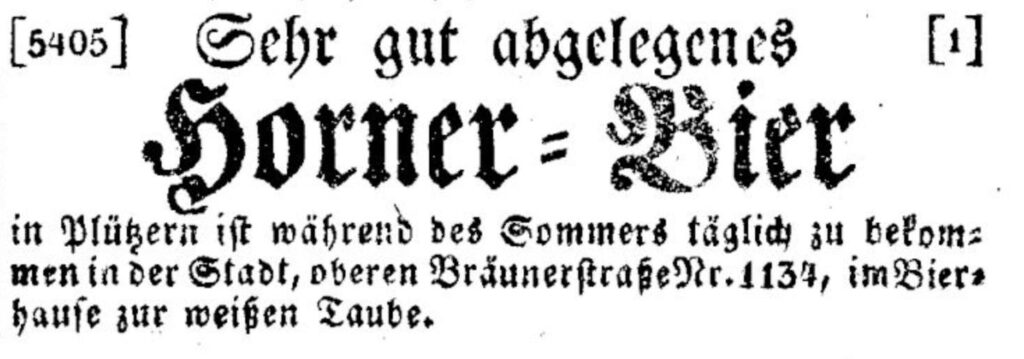

Speaking of beer history education, Craft Beer & Brewing published a great article by Jeff Alworth summarizing the history of Vienna Lager, as well my historic reconstruction of the original Vienna Lager as it was brewed in the 1870s. On top of that, another book touching the subject of Vienna Lager was published, unfortunately in German only. Die Geschichte der Brauerei Schwechat, co-authored by Schwechater brewmaster Andreas Urban, which dissects the history of Schwechater brewery and the Dreher family in greatest detail, even better than my own book, with a large amount of previously unpublished pictures. It very much focuses on the brewery itself, though, so if you’re interested in Vienna Lager itself or don’t understand German, I can still recommend my own book. 😉

My views may be skewed, as I’ve been immersed in the whole topic of Vienna Lager for quite a while now, but at least my impression is that there is indeed an increased interest in the beer style. I’m very glad about that, as I still think it’s a fantastic beer. Donzoko’s and Braybrooke’s collaboration is just the latest interpretation of the style, but I’m sure it won’t be the last. In the “German Brewing” Facebook group, pictures of both home-brewed and commercially brewed Vienna Lager are posted at least semi-regularly, people on various social media platforms contact me to tell me about their latest home-brewed examples, and even I, together with a friend, recently brewed a 10° Abzugsbier version (well, it turned into a 11° beer as we overshot our expected efficiency) which is currently lagering. So, 2021 may indeed be the year of Vienna Lager.