This is the third part in my series about some of the excellent lager beer that I had on our trip to the US in June 2024. After almost a week in Chicago, we flew to Austin, TX for a change in scenery and culture. While a big part of our visit to Austin was about experiencing Texas barbecue, we still visited a few of breweries, one of which especially stood out.

Live Oak Brewing Company (Del Valle, TX): Trailblazers of Texas Craft Beer

There are others who have told the story of Live Oak, located just outside Austin, TX, much better than I ever could, like Ruvani de Silva, who called it “Bamberg on the Colorado” in her article for Good Beer Hunting from 2022.

We had actually gotten in touch with Ruvani a few months before our trip and said we’d meet up for a few beers. As things worked out, we agreed to meet her and her husband Justin at Live Oak. Parallel to that, Tom Beckmann of Goldfinger also gave me the contact details of Dusan Kwiatkowski, Live Oak’s head brewer. Arriving at the brewery, we were greeted by Dusan and quickly joined by Chip McElroy, one of Live Oak’s co-founders. This all very quickly turned into a conversation of beer nerds talking about beer nerd things, followed by even more beer nerd talk when Ruvani and Justin arrived.

Beer-nerd alert!!A fab night chatting all things beer history, styles, ingredients & culture with fellow beer writer @akrennmair.bsky.social ,his lovely wife @louise.krennmair.bsky.social & @LiveOakBrewing ‘s dream-team Chip & Dusan, while tucking into their ever-brilliant brews – cheers y’all!🤠🍻👍🏽

— Amethyst Heels / Ruvani de Silva (@amethystheels.bsky.social) Jun 7, 2024 at 6:06 PM

[image or embed]

I had brought a bottle of Knoblach Hell for Ruvani as a small gift from Germany, and she decided to share it with everyone, while I was asked to sign the brewery’s copy of my Vienna Lager book.

Dusan and Chip were so nice to invite us again the next day to actually show us around the brewery and hang out a bit more. Dusan even dropped us off at the Airbnb we were staying and picked us up again, as he happened to live basically around the corner.

Live Oak is a true trailblazer of Texas craft beer. When they started out in 1997, they basically had to make things work with the little funding they had, in a state that at the time did not have much microbrewing going on yet (to this day, Live Oak is Texas’ 7th-oldest operating brewery).

And what they were doing seemed very unusual at the time, namely to have a lager-focused brewery. To this day, Live Oak’s flagship beer is Pilz, a Czech-style pale lager, and they started out with just that beer because it was what the co-founders Chip McElroy and Brian “Swifty” Peters wanted to drink. Since then, the range of beer has grown substantially, but the focus on lager and Central European beer styles is still there (even the two IPAs on the menu when we visited were bottom-fermented Cold IPAs).

The first beer I had at the brewery was Big Bark. They call it an amber lager but it really is a Vienna Lager, and a pretty good one, too. Pilz was equally good, and even better straight from the Zwickel, which is how Chip served it to us.

I tried all the classic styles, and they were all as good as they could be. The Hefeweizen caught me out in how poor my tasting skills are, as I misperceived the clove as banana. The Grodziskie at 3.0% ABV was absolutely on point, while the Schwarzbier captured the essence of the style: definitely a lot more flavourful and complex than Köstritzer, probably the baseline for the style, without getting too malty or full-bodied and/or verging into Czech Dark Lager territory (like some Franconian examples such as Neder Schwarze Anna do). Gold is their German Pilsner that I also couldn’t fault. Two friends of mine had told me beforehand that they actually preferred Live Oak Gold to Live Oak Pilz, and I get why. Personally, I found both equally good

Their latest beer on tap was Lyghte, a 3.2% American Light Lager, and it was absolutely gorgeous (for the style). Just the perfect lower-ABV beer for the summer heat in Texas, and unlike the classic big brewery brand examples of the style, full of flavour.

One thing I found particularly interesting was how both Chip and Dusan were drinking their own beer. More than once, Chip ordered a “Pilziskie”, a pour of half Pilz and half Grodziskie. I of course also had to try that, and yes, I get the appeal: just a hint of smoke (the pure Grodziskie doesn’t have much smoke aroma in the first place), and slightly less alcohol than Pilz. Dusan on the other hand drank a “Bark Lyghte” when he welcomed us, a blend of Big Bark and the new Lyghte. I found that one even better, as the malt character of Big Bark was still there, just as an overall lighter beer. Lower-ABV Vienna Lager, aka Abzugbier, was a thing after all (and still is if you brew it yourself). Louise suggested a “Spud Lyghte” blend if they ever brew their “Spudweiser” potato beer again.

As for being a trailblazing brewery, Live Oak was also very early in brewing a Grodziskie, and even brewed a collaboration once with Browar Grodzisk in Poland back in 2018. They even went all to way to specifically use Nowotomyski hops, a Polish hop variety that had been on the brink of extinction. Live Oak have since then formed a closer relationship to Polish hop-growers and hop-breeders, also had some of them over for a visit in Austin, and brew a seasonal Polish-style Pils called “Piwko Pils” using Polish hops. Stan Hieronymus’ 2019 article about Grodziskie tells us even more about Live Oak’s approach to the beer style.

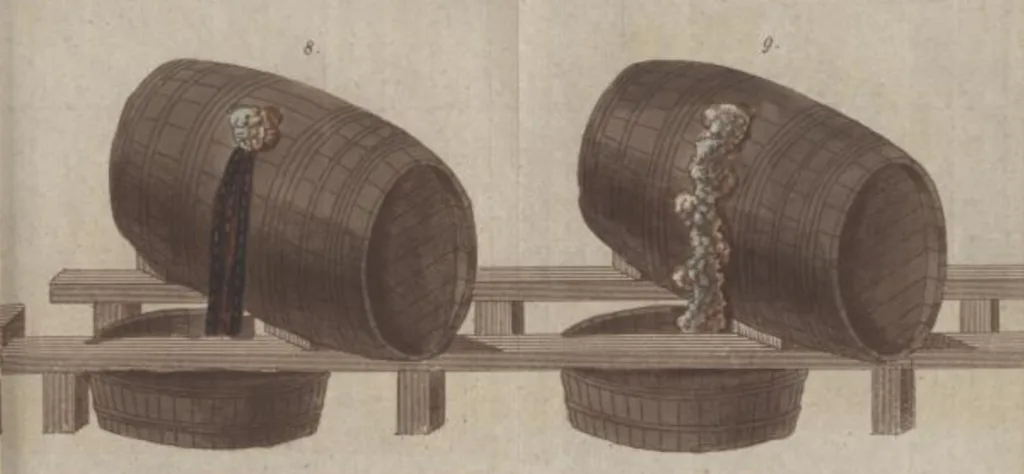

Like most lager-focused breweries, Live Oak also love their decoction mashing. Their kit is not optimal for it, as they have a setup of a heatable mash tun, a lauter tun and a kettle. They actually use the mash tun for boiling the decoctions, but it means extra effort, as for every decoction, the portion of the mash not to be boiled needs to be pumped over into the lauter tun, then the decoction needs to be brought to a boil, then pumped over into the lauter tun, and finally the whole mash needs to be pumped back into the mash tun. It makes the process last quite a bit longer, but as Chip and Dusan said, it’s definitely worth it. They hope to eventually extend the brewery with a smaller kettle dedicated to just boiling decoctions which should significantly improve the brewing process and turnaround times.

Having been a trailblazer of Texas craft beer, Live Oak probably felt it the most how COVID and places serving draft beer basically shutting down completely leveled the field within the industry. When Live Oak started out, they had a hard time getting their beer into bars, and it was a lot of work for them to establish themselves on the market. Chip said that most of their draft accounts got wiped out, and instead of being one of only very few craft beer options in the state of Texas when they started out, post-COVID they now have to compete with 60+ other breweries to get their beers back into bars and restaurants. The trend towards drinking at home during COVID only partially covered the loss in draft beer business, and Live Oak still isn’t at pre-COVID production volumes.

Live Oak are still firmly rooted in their local community, though. Texas supermarket chain H-E-B is apparently their biggest customer (when we went shopping there once, I bought a six pack of Big Bark), while both barbecue places we went to, Franklin Barbecue and Micklethwait Craft Meats, had Live Oak beers on offer (for the record, I had Lone Star at Franklin because it’s probably the most iconic Texan beer and so I just had to have it at one of the best barbecue restaurants in the state of Texas, and Stiegl Grapefruit Radler at Micklethwait because it was just so incredibly hot).

If you’re a subscriber to Craft Beer & Brewing magazine, Live Oak have published recipes to two of their beers in the magazine, in particular for their Grodziskie and for Schwarzer Rauch, their smoked Schwarzbier.

And even totally outside the topic of beer, Live Oak’s taproom is absolutely worth a visit. There’s a food truck there, a large outdoor seating area, and if you’re into Disc Golf (to be honest, I’ve not heard of it before visiting Live Oak), they have a large Disc Golf course, designed by head brewer Dusan.

In any case, Live Oak Brewing just outside of Austin is absolutely worth a visit, and was one of my top 4 breweries that I visited in the US.