In 1992, the EU introduced the Protected Designation of Origin (PDO) framework to preserve the designations of origin of food- and drink-related products. In particular, three different systems exist: PDO, Protected Geographic Indication (PGI), and Traditional Specialities Guaranteed (TSG). Each of these are easily recognizable through their logos which you may have seen on food packaging.

And of course, a number of these are registered for specific beers. Out of curiosity, I looked into some of these and realized that some of them are rather specific. So I wondered… how many types of beer are registered as any of these geographic indications in a specific enough way to turn them into beer style guidelines akin to the BJCP or the Brewers Association’s Beer Style Guidelines. Turns out: quite a few. So here are my PGI Beer Style Guidelines (see at the end for a brief discussion):

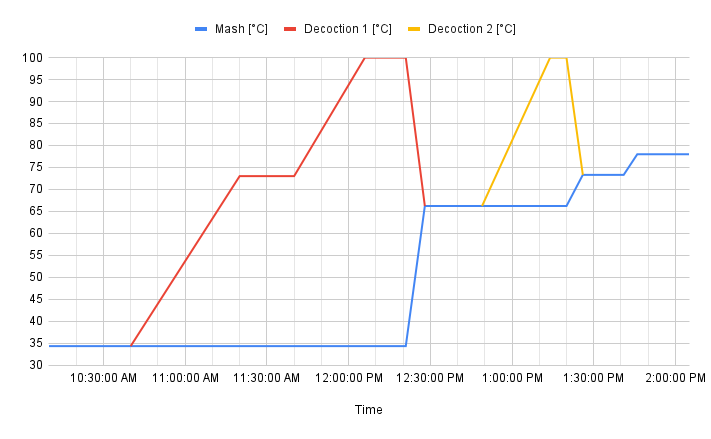

Munich Beer

(source)

Helles

OG °P: 11.4 – 11.9

% ABV: 4.7 – 5.4

EBC: 5.0 – 8.5

IBU: 14.0 – 25.0

Light yellow, pale, palateful, pure, smooth, mildly to pleasantly hopped, delicately spicy to spicily fresh with a pleasant bitterness depending on the brewing process.

Export Hell

OG °P: 12.5 – 12.8

% ABV: 5.5 – 6.0

EBC: 5.5 – 7.5

IBU: 15.0 – 26.0

Light yellow, highly attenuated (until bright), palateful, ranging from mild, mellow-smooth through to strongly spicy, delicately hopped and delicate bitterness.

Export Dunkel

OG °P: 12.5 – 13.7

% ABV: 5.0 – 5.9

EBC: 42.0 – 59.9

IBU: 15.0 – 24.0

Mellow, smooth, malty aroma to strong, Munich malt sometimes dominant.

Pils

OG °P: 11.5 – 12.5

% ABV: 4.9 – 5.8

EBC: 5.5 – 7.0

IBU: 30 – 38

Slightly sharp, delicate, fine, hoppy bitterness, hoppy accents through to hoppy aroma, light, elegant, sparkling.

Leichtes Weißbier

OG °P: 7.7 – 8.4

% ABV: 2.8 – 3.2

EBC: 11.0 – 13.0

IBU: 13.0 – 15.0

Refreshing, effervescent, tangy, cloudy with yeast, typical top-fermented Weißbier taste.

Kristall Weizen

OG °P: 11.5 – 12.4

% ABV: 4.9 – 5.5

EBC: 7.5 – 12.5

IBU: 12.0 – 16.0

Effervescent, very tangy, filtered bright, clear, sparkling, top-fermented note, typically top-fermented.

Hefeweizen Hell

OG °P: 11.4 – 12.6

% ABV: 4.5 – 5.5

EBC: 11.0 – 20.0

IBU: 12.0 – 20.0

Highly attenuated, naturally cloudy, typical top-fermented character, tangy, refreshing, effervescent, sparkling, sometimes yeasty, Weißbier aroma.

Hefeweizen Dunkel

OG °P: 11.6 – 12.4

% ABV: 4.5 – 5.3

EBC: 29.0 – 45.0

IBU: 13.0 – 16.0

Naturally cloudy, mellow, malty taste/character, top-fermented note/character.

Märzen

OG °P: 13.2 – 14.0

% ABV: 5.3 – 6.2

EBC: 8.0 – 32.5

IBU: 21.0 – 25.0

Very mellow, palatable, mild, altbayerisch aroma to malty aroma, very mild bitterness.

Bockbier

OG °P: 16.2 – 17.3

% ABV: 6.2 – 8.1

EBC: 7.5 – 40.0

IBU: 18.0 – 32.5

Highly attenuated, ranging from mellow, palateful, smooth, aromatic, via delicately hopped, slightly sharp to well hopped, sometimes spicy in character.

Doppelbock

OG °P: 18.2 – 18.7

% ABV: 7.2 – 7.7

EBC: 44.0 – 75.0

IBU: 18.0 – 28.0

Strong, powerful, spicy, full-bodied, malty taste.

Leichtbier

OG °P: 7.5 – 7.7

% ABV: 2.7 – 3.2

EBC: 5.5 – 7.0

IBU: 24.0 – 26.5

Slightly sharp fine taste.

Diät Pils

OG °P: 8.5 – 9.3

% ABV: 4.3 – 4.9

EBC: 5.0 – 6.5

IBU: 26.0 – 30.0

Low in carbohydrates, slightly sharp, dry taste.

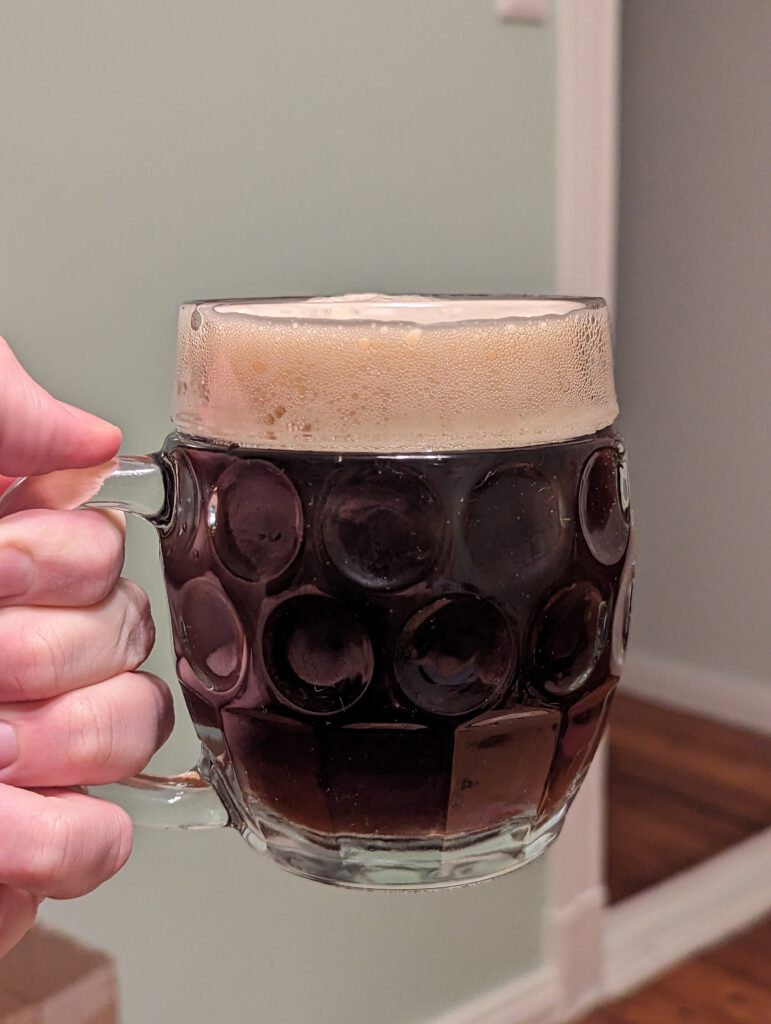

Schwarzbier

OG °P: 11.3

% ABV: 4.8

EBC: 70.0

IBU: 17.0

Slightly spicy malty aroma.

ICE-Bier

OG °P: 11.2

% ABV: 4.9

EBC: 6.5

IBU: 20.0

Harmonious, mellow, palateful.

Nähr-/Malzbier

OG °P: 12.3 – 12.7

% ABV: 0.0 – 1.2

EBC: 65.0 – 90.0

IBU: 8.0 – 15.0

Low in alcohol, very mildly attenuated, malty, spicy, very weakly hopped.

Oktoberfestbier

OG °P: 13.6 – 14.0

% ABV: 5.3 – 6.6

EBC: 6.0 – 28.0

IBU: 16.0 – 28.0

Light, golden, amber colours or dark, ranging from palateful, very mellow, smooth or malty aroma through to slightly hopped with a very mild bitterness or a powerful, slightly sweet taste.

Czech Beer

(source)

Pale Lager

OG °P: 11.00 – 12.99

% ABV: 3.8 – 6.0

EBC: 8.0 – 16.0

IBU: 20 – 45

Dark Lager

OG °P: 11.00 – 12.99

% ABV: 3.6 – 5.7

EBC: 50 – 120

IBU: 20 – 45

Pale Draught

OG °P: 8.00 – 10.99

% ABV: 2.8 – 5.0

EBC: 7.0 – 16.0

IBU: 16 – 28

Dark Draught

OG °P: 8.00 – 10.99

% ABV: 2.6 – 4.8

EBC: 50 – 120

IBU: 16 – 28

Light Beer

OG °P: 7.99% max

% ABV: 2.6 – 3.6

EBC: 6.0 – 14.0

IBU: 14 – 26

Bavarian Beer

(source)

Schankbier

OG °P: 7.0 – 9.0

% ABV: 2.5 – 3.5

EBC: 5 – 20

IBU: 10 – 30

bottom-fermented; a full-bodied, soft, fizzy beer with fewer calories and less alcohol by volume than Vollbier (full-strength beer).

Hell/Lager

OG °P: 11.0 – 12.5

% ABV: 4.5 – 5.5

EBC: 5 – 20

IBU: 10 – 25

bottom-fermented; a slightly aromatic, light, full-bodied, mild beer.

Pils

OG °P: 11.0 – 12.5

% ABV: 4.5 – 6.0

EBC: 5 – 15

IBU: 30 – 40

bottom-fermented; a distinctive, slightly sharp beer with a bitter edge lent by the hops.

Export

OG °P: 12.0 – 13.5

% ABV: 4.5 – 6.0

EBC: 5 – 65 (hell – dunkel)

IBU: 15 – 35

bottom-fermented; a full-bodied, well-rounded bitter taste.

Dunkel

OG °P: 11.0 – 14.0

% ABV: 4.5 – 6.0

EBC: 40 – 65

IBU: 15 – 35

bottom-fermented; a full-bodied beer with a malty aroma.

Schwarzbier

OG °P: 11.0 – 13.0

% ABV: 4.5 – 6.0

EBC: 65 – 150

IBU: 15 – 40

bottom-fermented; a beer with a roasted aroma, a slight malty aroma and a bitter edge lent by the hops.

Märzen/Festbier

OG °P: 13.0 – 14.5

% ABV: 5.0 – 6.5

EBC: 7 – 40

IBU: 12 – 45

bottom-fermented; a malty-flavoured beer with a slightly bitter edge lent by the hops.

Bock

OG °P: 16.0 – 18.0

% ABV: 6.0 – 8.5

EBC: 7 – 120 (hell – dunkel)

IBU: 15 – 40

bottom-fermented; a full-bodied, malty-flavoured beer with a delicate aroma of hops.

Doppelbock

OG °P: 18.0 – 21.0

% ABV: 7.0 – 9.5

EBC: 10 – 150 (hell – dunkel)

IBU: 15 – 35

bottom-fermented; a distinctly full-bodied, malty-flavoured beer with a hint of caramel.

Weizenschankbier

OG °P: 7.0 – 9.0

% ABV: 2.5 – 3.5

EBC: 7 – 30

IBU: 5 – 20

top-fermented; a fizzy beer with the aroma of yeast.

Weizenbier

OG °P: 11.0 – 13.5

% ABV: 4.5 – 5.5

EBC: 5 – 65 (hell – dunkel)

IBU: 10 – 30

top-fermented; a fruity beer with an aroma of wheat and a slightly malty flavour.

Kristallweizen

OG °P: 11.0 – 13.5

% ABV: 4.5 – 5.5

EBC: 5 – 18

IBU: 5 – 20

top-fermented; a carbonated beer with the aroma of wheat.

Rauchbier

OG °P: 11.0 – 14.5

% ABV: 4.5 – 6.0

EBC: 30 – 60

IBU: 20 – 30

bottom-fermented; a full-bodied beer with a smoky flavour.

Kellerbier/Zwickelbier

OG °P: 11.0 – 13.5

% ABV: 4.5 – 6.0

EBC: 5 – 60

IBU: 10 – 35

bottom-fermented; a beer with a slightly bitter edge lent by the hops, unfiltered, tapped from the lower part of the barrel, with a low carbon dioxide content.

Eisbier/Icebier

OG °P: 11.0 – 13.0

% ABV: 4.5 – 5.0

EBC: 5 – 20

IBU: 10 – 25

bottom-fermented; very mild and soft.

Kulmbacher Beer

(source)

Alkoholreduziert

OG °P: 7.3 – 7.9

% ABV: 2.8 – 3.2

EBC: 5.0 – 7.0

IBU: 25 – 30

A mellow, slightly sharp-tasting beer with the trademark flavour of Kulmbacher Pils.

Pils

OG °P: 11.1 – 11.8

% ABV: 4.7 – 5.2

EBC: 5.0 – 11.0

IBU: 23 – 38

A mellow, lightly hopped beer with a fresh, delicately bitter character.

Lager hell

OG °P: 11.0 – 13.0

% ABV: 4.8 – 5.2

EBC: 6.5 – 12

IBU: 18 – 26

A balanced, mellow, mild-flavoured beer.

Lager dunkel

OG °P: 11.5 – 13.0

% ABV: 4.8 – 5.2

EBC: 30 – 40

IBU: 18 – 22

A mellow, malty-aromatic beer.

Export hell

OG °P: 12.1 – 13.0

% ABV: 4.7 – 5.9

EBC: 6.5 – 15

IBU: 22 – 30

A smooth, mildly aromatic-flavoured beer.

Export dunkel

OG °P: 12.1 – 13.0

% ABV: 4.7 – 5.6

EBC: 35 – 100

IBU: 22 – 32

This beer has a distinctively smooth and lightly hopped flavour.

Festbier

OG °P: 13.0 – 13.7

% ABV: 5.4 – 5.9

EBC: 10 – 13

IBU: 23 – 25

This is a strong, aromatic, slightly sweet beer with a robust colour.

Bock dunkel

OG °P: 16.0 – 16.8

% ABV: 6.4 – 6.8

EBC: 25 – 40

IBU: 21 – 27

This is lightly hopped, medium-coloured strong beer.

Starkbier hell

OG °P: 24.0 – 30.0

% ABV: 9.0 – 11.2

EBC: 30 – 38

IBU: 15 – 26

This is a lightly hopped, mediumcoloured strong beer.

Starkbier dunkel

OG °P: 24 – 30

% ABV: 9.0 – 11.2

EBC: 60 – 100

IBU: 15 – 26

This malty aromatic, dark, robust strong beer is the strongest beer in the world: EKU (Erste Kulmbacher Actienbrauerei) 28.

Hefeweizen alkoholreduziert

OG °P: 7.3 – 8.0

% ABV: 2.8 – 3.4

EBC: 7.0 – 15.0

IBU: 13 – 17

This is a light-flavoured, typical Weizenbier (literally “wheat beer”).

Hefeweizen hell

OG °P: 12.2 – 12.9

% ABV: 5.0 – 5.6

EBC: 10.0 – 15.0

IBU: 13 – 17

This is a slightly sweet, robust typical top-fermented beer.

Hefeweizen dunkel

OG °P: 12.2 – 12.9

% ABV: 4.9 – 5.4

EBC: 60 – 80

IBU: 13 – 17

This is a malty-aromatic, dark beer with the typical characteristics of a top-fermented beer.

Lower Francian (“Mainfranken”) Beer

(source)

Leichtbier

OG °P: 7 – 9

% ABV: 2.4 – 2.9

EBC: 6 – 12

IBU: 15 – 30

Hell/Lager

OG °P: 11 – 12.5

% ABV: 4.5 – 5

EBC: 7 – 15, 40+

IBU: 12 – 30

Pils

OG °P: 11 – 13

% ABV: 4.8 – 5.2

EBC: 6 – 12

IBU: 25 – 35

Schwarzbier

OG °P: 11 – 13

% ABV: 4.8 – 5.3

EBC: 40 – 80

IBU: 25 – 35

Export

OG °P: 12 – 13.5

% ABV: 4.9 – 5.5

EBC: 6 – 15, 40 – 80

IBU: 16 – 25

Märzen/Festbier

OG °P: 13 – 14

% ABV: 5.0 – 5.7

EBC: 10 – 20

IBU: 16 – 30

Weizenbier

OG °P: 11 – 13.5

% ABV: 4.8 – 5.5

EBC: 7 – 20, 40+

IBU: 12 – 20

Weizenbock

OG °P: 16 – 18

% ABV: 5.5 – 7.2

EBC: 7 – 20, 40+

IBU: 12 – 20

Bock/Doppelbock

OG °P: 16 – 19

% ABV: 5.5 – 7.2

EBC: 10 – 20, – 80

IBU: 20 – 30

Českobudějovické (Budweiser) Beer

(source)

Pale Lager

OG °P: 11.4 – 12.3

% ABV: 4.6 – 5.3

EBC: 9 – 13

IBU: 20 – 24

Aroma: medium to strong intensity, pronounced aroma of fine aromatic Žatec hops.

Taste: bitterness of slight to medium intensity, mild to slightly harsh character, medium to full-bodied taste with a sweetish aftertaste, pronounced sharpness.

Kräusened Pale Lager

OG °P: 11.4 – 12.3

% ABV: 4.6 – 5.3

EBC: 9 – 13

IBU: 20 – 24

Aroma: medium to strong intensity, pronounced aroma of fine aromatic Žatec hops.

Taste: bitterness of slight to medium intensity, mild to slightly harsh character, full- to very full-bodied taste with a sweetish aftertaste, pronounced sharpness.

Pale draught beer

OG °P: 9.5 – 10.1

% ABV: 3.5 – 4.5

EBC: 8 – 12

IBU: 18 – 21

Aroma: medium to strong intensity, pronounced aroma of fine aromatic Žatec hops.

Taste: bitterness of slight to medium intensity, slightly harsh character, medium-bodied taste with a sweetish aftertaste, pronounced sharpness.

Special beer

OG °P: 16.0 – 17.0

% ABV: 7.4 – 8.2

EBC: 11 – 17

IBU: 24 – 28

Aroma: medium to strong intensity, pronounced aroma of fine aromatic Žatec hops.

Taste: bitterness of medium to strong intensity, mild to slightly harsh character, full- to very full-bodied taste with a sweetish aftertaste, pronounced sharpness.

Non-alcoholic beer

OG °P: 3 – 4

% ABV: 0.2 – 0.5

EBC: 5 – 7

IBU: 22 – 26

Aroma: medium intensity, pronounced aroma of fine aromatic Žatec hops, slightly reminiscent of hopped wort.

Taste: bitterness of medium intensity, slightly harsh character, light-bodied taste, pronounced sharpness, with a hint of hopped wort.

Dark lager

OG °P: 10.5 – 12.0

% ABV: 4.0 – 5.3

EBC: 60 – 120

IBU: 20 – 35

Aroma: medium to strong intensity, pronounced aroma of fine aromatic Žatec hops and roasted malt.

Taste: bitterness of medium to strong intensity, mild to moderately harsh character, full- to very full-bodied taste with a dry, roasted aftertaste, pronounced sharpness.

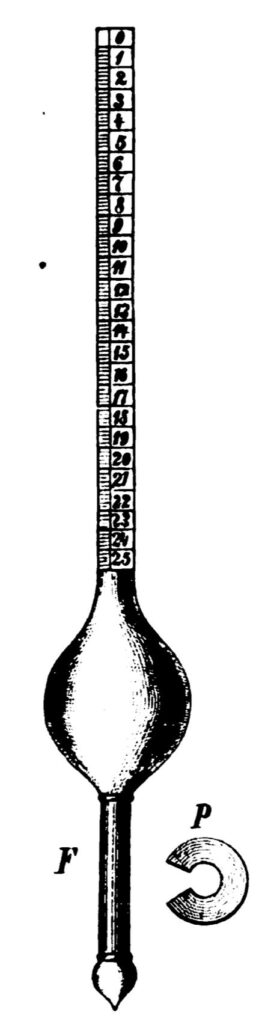

Lithuanian Beer

Kaimiškas Jovarų alus

(source)

OG °P: 12.0 – 15.0

% ABV: 5.6 ± 1.0

EBC: 15 – 38

IBU: 10 – 30

Colour: the colour ranges from golden yellow to golden brown (amber).

Appearance: the beer froths when poured into a jug or glass, usually creating a tall head of thick, white foam. Characteristic turbidity as a result of the yeast sediment.

Nose: a notable aroma of yeast, bread, caramel and fruit.

Taste: an intense, malty beer taste. Characteristic bitter taste of hops with a hint of yeast, berries, caramel, hazelnuts, herbs and citrus fruit. If natural honey is added, there is a hint of honey.

Discussion

What is very noticeable is that all these guidelines are awfully specific. In particular the Bavarian groups of beer styles (Munich, Mainfranken, Kulmbach, Bavaria) have a significant amount of overlap in terms of styles, and of course, they mostly contradict each other in terms of what’s an outlier but still “within style” for original gravity, ABV, bitterness and colour. Some styles even seem very restricted, like the maximum bitterness of a Munich Pils would be 38 IBU, 40 for a Bavarian Pils, 38 for Kulmbacher Pils (which in turn could be as low as 23 IBU), or even only 35 for Lower Franconian Pils.

The next question is of course: how would any of this be enforced? Several of the official documents list contact addresses for fraudulent usage of the PGI term, but what would be fraudulent here? If a Bavarian brewed a 45 IBU Pils and put a Bavarian Beer PGI logo on their bottles, would that constitute fraud and a misuse of the PGI logo? Or are these style descriptions just vague suggestions? That’s been entirely unclear to me.

A funny detail to be found in the list of styles is a former fad in German brewing that has died off since the original filing of these documents: one of them is Diät Pils, a term that has actually been discontinued in Germany about a decade ago when it was prohibited to produce and advertise food products specifically for diabetics. Another one is Eisbier or “ice beer” (not to be confused with Eisbock, a freeze-distilled strong beer), where beer is lagered at colder temperatures than normal and ice crystals are filtered out which allegedly also removes some of the bitterness compounds and thus produces a very mild-tasting beer. In fact, both fads have fallen so much out of fashion that amendments have been filed to remove both from the PGI documents.

One thing I also need to note is that I only included some of the beer-related PGI filings. Some were not specific enough (like Kölsch, which just seems to be a translation of the Kölsch-Konvention), others were a bit ridiculous because they are so hyper-regional that at the time of filing, only 2 breweries existed there (like in the case of Hofer Bier from Hof/Saale in Bavaria). No PDO filings for beer seem to exist. There exist several TSG filings for various beers, though, but I chose to not include them because they were not quite specific enough.